Failure analysis

Overview

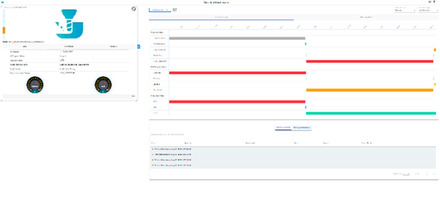

In section "Failure analysis", error states that occur for a machine tool equipped with a SINUMERIK control system can be identified and evaluated. As a result of the higher transparency, all of the required service work can be executed more efficiently and machine downtimes can be reduced.

It is important that these errors are checked, and based on a combination comprising "Machine status", "NC program status" and "Operating mode", action is taken so that users can define the cause therefore avoiding that these errors are triggered.

The section contains a list of the technical errors and NC stops that occurred 60 seconds before and remain for an additional 60 seconds. Alarms +/- 60 seconds are listed for these technical errors and NC stops.

Parameters

|

Parameters |

Description |

|---|---|

|

Error type |

|

|

Technical error |

Displays a technical error. |

|

NC program error |

Displays an NC program error |

|

Alarms |

|

|

From |

Displays the instant in time |

|

Alarm number |

Displays the alarm number |

|

Deletion information |

Displays the deletion information |

|

Alarm text |

Displays the alarm text |

|

Source |

Displays the source |

|

From (client) |

Displays the client |

Procedure

-

Click on the dots in the "Machine description" area.

-

Select "Failure analysis".

The failure analysis is displayed in the lower right-hand window.

-

Click on the diagram to select between:

-

Machine status: Technical error

-

NC program status: stops, freezes

-

-

Select one of the dots to scroll there.

All the associated technical errors are listed in the table.