Prerequisites¶

The process data used to train the model must be available as IoT timeseries in a single aspect for the selected asset. To generate effective predictions, the data must be updated with the new data at the same frequency as the historical data used to train the model. The process data must contain following variables:

- _time (timestamp) - Variable to define date and time of each data point in IoT timeseries.

- Input features (double) - One or more numeric process parameters used as predictors for the process model.

- Filtering features (integer or string) - One or more numeric or text process parameters used to define the manufacturing phase.

- Identifier (string) - The parameter to identify produced parts is used for the aggregation of process parameters related to each part's manufacturing process phase. This must be same for each data point associated with the selected part and must be unique for all parts.

The quality data used to train the model must be available as a CSV file in the Integrated Data Lake (IDL). This file is extracted from the quality management system used in specific manufacturing process and the file must contain a data table with columns containing the variables listed below:

- Timestamp (timestamp) - Variable to define the date and time of the quality measurement result.

- Identifier (string) – Variable containing unique serial number of parts.

The values of the identifier should have its counterparts in the Identifiers available in the selected IoT timeseries process data.

- Target (double) – Numeric variable containing target quality feature to train the model.

- Tolerance Low (double) – Low tolerance limit used for quality acceptance check.

- Tolerance High (double) – High tolerance limit used for quality acceptance check.

Additional aspect should be available in the IoT model for a selected asset to store quality prediction results. This aspect should contain variables to store:

- Target (double) – Variable to store prediction result.

- Tolerance Low (double) – Variable to store low tolerance limit.

- Tolerance High (double) – Variable to store high tolerance limit.

- Identifier (string) - Variable containing unique serial number of parts. If the Timestamp is used as an Identifier, no additional Identifier variable is required.

These variables must have the same names as the corresponding columns in the quality data file.

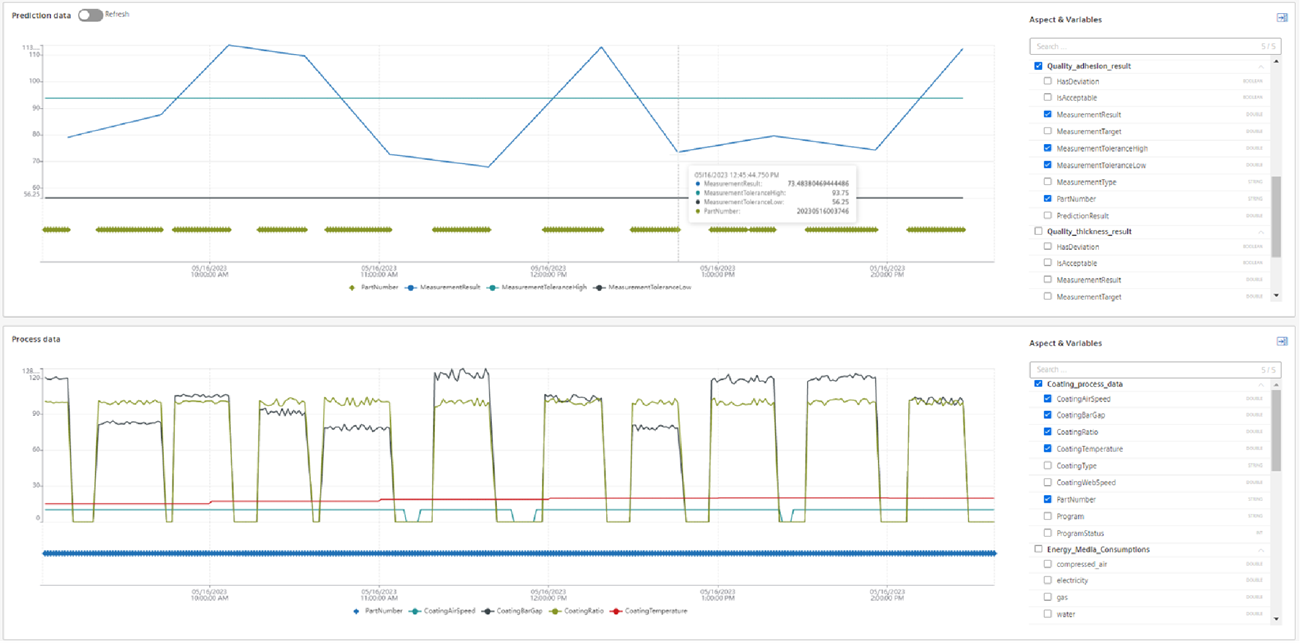

An example of the IoT data model used to work with the manufacturing process and quality data is shown in the image.