Introduction¶

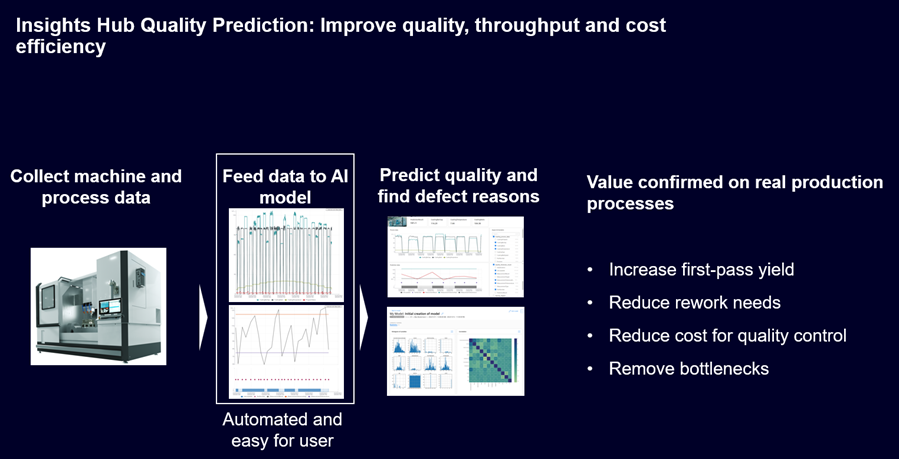

Siemens Digital Industries Software announces a new industrial solution "Insights Hub Quality Prediction". This solution combines the benefits of Industrial IoT technology provide by Insights Hub with Machine Learning (ML) technology to predict product quality results based on manufacturing machine data.

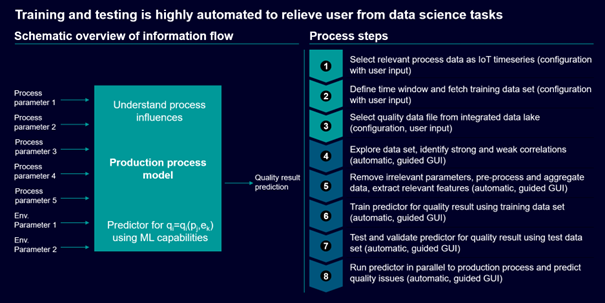

Insights Hub Quality Prediction represents a powerful solution for Production Managers, Quality Engineers, Manufacturing Engineers and Machine Operators to perform root cause analysis of the production process and discover complex relationship between production machine parameters and resulting product quality metrics based on historical manufacturing data. The application provides a user-friendly interface and automatic functions for creating, training, and evaluating ML models without requiring extensive knowledge in data science or statistics.

The application's ML model of the process is used to predict resulting product quality in real time with the input of actual manufacturing parameters before a defect and the quality loss. The use of this predictive functionality in the manufacturing process can reduce the number of inspections and measurements, increasing the confidence in product quality conformance. Quality prediction can be used for active manufacturing process control to take preventive action when quality issues are anticipated in the actual manufacturing conditions.

Implementing reliable quality prediction in the manufacturing process increases productivity and yield lowering overall product manufacturing costs and lead time, with significant monetary and customer satisfaction benefits. It can also reduce the need for manual quality inspection avoiding related capital and operating costs.

The information regarding the prediction model settings and the evaluation of the model results is provided in the video below and the description is explained in document further.

Capabilities¶

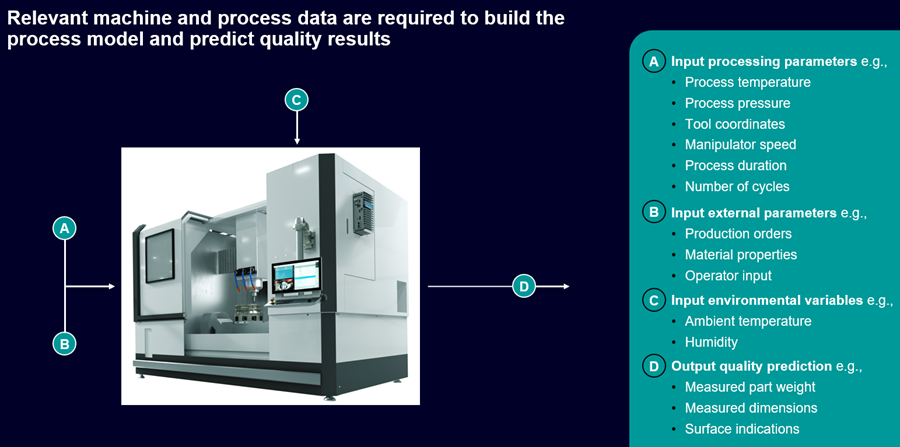

Quality Prediction is a dedicated Insights Hub solution to predict quality parameters for produced goods based on the manufacturing process data. This enables predictive quality improvement by establishing the relationship between relevant manufacturing process parameters and corresponding quality characteristics with implementation of machine learning (ML) approach.

Key capabilities of Quality Prediction Hub are:

- Automatic quality prediction using production data analytics.

- Wizard-based user interface for selecting machine data, quality data and ML model parameters.

- Visualization of machine and quality data, including run-time charts, distribution histograms and correlation map.

- Automatic pre-processing, aggregation, and feature generation for machine and quality data.

- Visualization of aggregated data with run-time charts, distribution histograms and correlation map.

- Automatic training of selected ML model to solve a regression problem for quality prediction.

- Visualization of prediction results with True vs Predicted values chart, Feature Importance diagram and Model Accuracy analysis.

- Automatic update of views for user role engineer and process operator.

- Output of predicted quality results in relation to specified tolerances.