Time Model¶

Time Model is one of the fundamental concepts of the Insights Hub OEE application. It is a representation of the production time and various downtimes of a plant. It describes how the total time of a plant is being divided into different time categories, which represent how the time is being used in the plant. By default, the Insights Hub OEE application has configured three major time categories for the calculation of overall equipment effectiveness. Using these time categories, users can set up the other time categories.

The main time categories of the Insights Hub OEE application are:

- Production Time: The Production time category accounts for all the run time of the machine or line.

- Availability Loss: The availability loss category gathers all the various machine or line stop states and downtimes that the user wants to classify as availability loss. This typically includes all types of downtime, change-over, cleaning phases, supply chain-related issues, or internal faults. It is up to the user to define what counts as an availability loss and what does not.

- Planned Stop: This category contains all stops that are intended by the user of the application. That could be, for example, planned maintenance, a shift break, a holiday, or simply a weekend, where the machines and lines are not producing. These times are not considered for the calculation of OEE but are important for the calculation of the Total Effective Equipment Performance (TEEP). Furthermore, no OEE is calculated during planned stops.

The following table shows which major time category impacts which KPI:

| KPI | Production Time | Availability Loss | Planned Stop |

|---|---|---|---|

| OEE | X | X | |

| TEEP | X | ||

| Availability | X | X | |

| Performance | X | ||

| Quality | X | ||

| MTTR | X | X | |

| MTBF | X | X |

The formulas for the KPIs calculation are described in Section OEE Standard Formulas.

The example given below explains the time model:

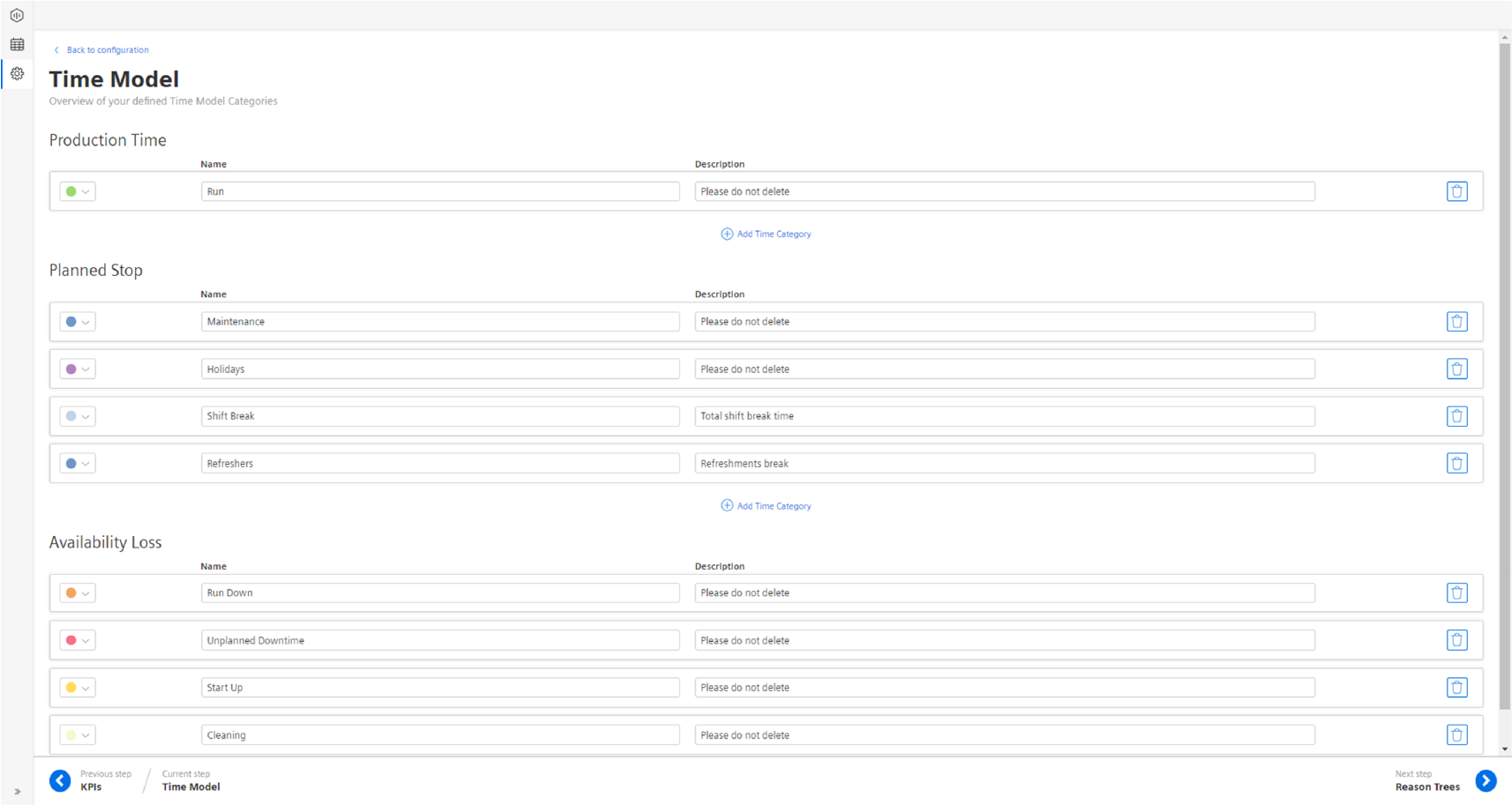

In this example, we have defined nine different time categories, which are inherited from the three major time categories:

- Production time: Under Production time, we have only defined a one-time category called Run, this represents when the machine or line is operating.

- Planned Stop: In this time category, we have defined multiple categories that stand for different stops in a factory, which are Holiday, Shift Break, Maintenance, and No Production. Whenever the machine status or configured calendar for a machine or line is in one of these time categories, then these times are counted towards the Planned stop and are not considered in the overall OEE calculation.

- Availability Loss: Under Availability Loss, we have defined multiple time categories which also represent different typical categories of availability losses. In our case, we have defined Unplanned Downtime, Cleaning, Run Down, and Start-Up. Whenever we are in a machine or line state, that is represented by one of the above-mentioned time categories, then this time is counted towards Availability Loss.

The definition of the time model is a crucial step to evaluate and understand the collected machine status. For more information to set up the time model, refer Section Configuring Time Model.

The states defined under Production Time and Planned Stop can also be utilized in the Calendar configuration to describe the state that the machine is in in a defined event. For more information, refer Section Configuring Calendar.

The following Section Reason Tree shows how the underlying time model is being utilized to build custom reason trees.