Products & Design Speed¶

Products and the associated design speed are the crucial elements to evaluate the machine or line performance KPI. The product or product code is required to understand the design speed that the machine or line should be operating at the time. The design speed provides information on the count that should be produced by the equipment in a specific time interval (second, minute or hour). Therefore, each product code that an equipment produces must have an associated design speed.

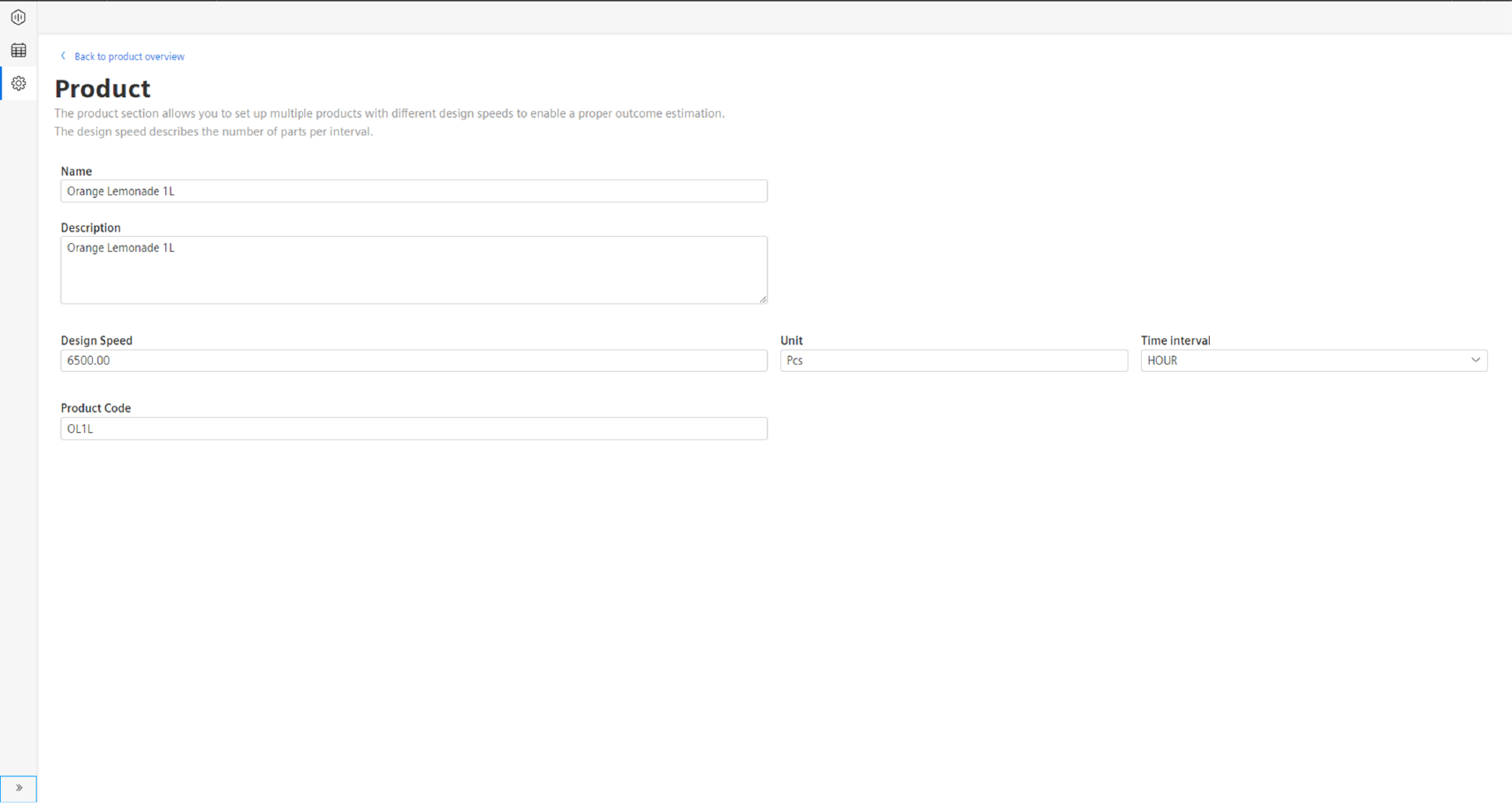

The image below is an example definition of a product and the relevant information:

The example above shows the information that an Insights Hub OEE user has to enter while configuring a new product.

In this case, the following product is configured:

- Product Name: Orange Lemonade 1L

- Description: Orange Lemonade 1L

- Design Speed: 6000

- Unit: Pieces (Pcs)

- Time Interval: Hour

- Product Code: OL10

Therefore, whenever Insights Hub OEE receives the product code “OL10”, it knows that Orange Lemonade in 1L should currently be manufactured at a speed of 6000 Pcs (or bottles) every hour.

Design speeds are typically determined by estimates and experience rather than by formal calculations. As a result, they can be changed over time, for example, if a machine has been upgraded by the factory operations team so that it can run faster. One reason to adjust the design speed of a product is when the Performance KPI is constantly above 100%. This is always a sign, that the initial design speed was set too low and needs to be further adjusted so that it does not manipulate the OEE calculation.