E-Kanban¶

An E-Kanban system is quite common in lean manufacturing environments. Based on a traditional Kanban system, the E-Kanban system is a progression of the typical Kanban system. Here, sensors and software are used to help automate the Kanban process. In a nutshell, before the use of an E-Kanban system, the Kanban process to reorder material was manual. Now, with the use of a sensor-based E-Kanban system, the process is enhanced so that the new material is automatically reordered by the system once a certain threshold / minimum level of containers is reached, within a material channel.

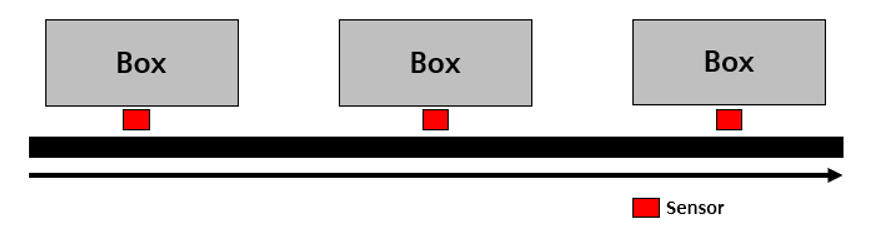

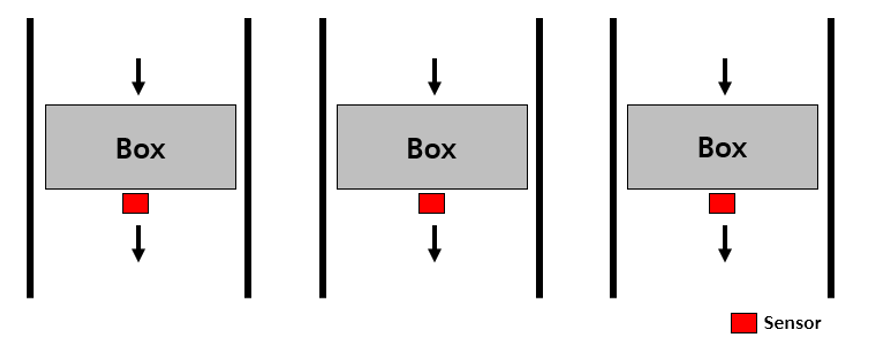

A material channel represents a physical way to store material containers. A material channel also consists of multiple positions, where material containers can be located. There are two ways to align these material channels. You can imagine multiple containers containing production material either one after another, or next to each other. (PICTURES OF TWO TYPES).

FIFO Channel (material boxes flow in a single direction):

Parallel Channel (material flows in a single direction from multiple lanes):

The pictures above show the two different types of material channels supported by the application. In the first picture, the material in the containers flows in one direction following the FIFO (first in first out principle). In the second picture, the containers are in parallel lanes, and it doesn’t matter in which order material is being consumed in the channel.

To make use of Insights Hub Intralogistics it is necessary, to have an E-Kanban solution, which automatically retriggers the material supply for the material channel to ensure a proper material flow. Following this prerequisite, it is necessary that the sensor information is accessible, in order to determine if the container position in the material channel is empty or filled.