Analysis package "Vibration Characteristic Values"¶

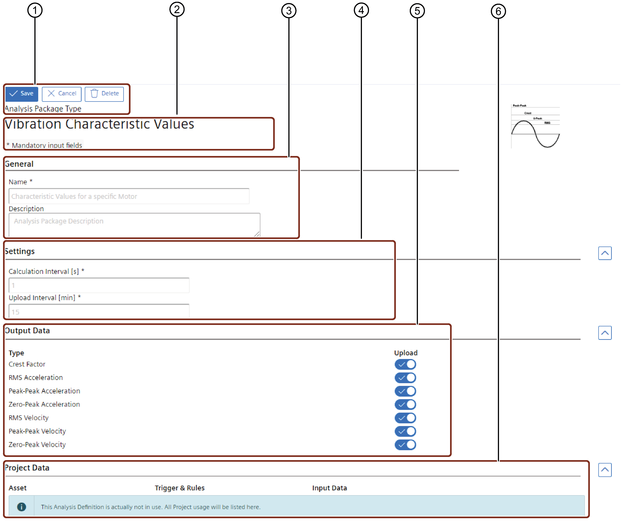

With the analysis package "Vibration Characteristic Values" you can create or edit your individual analysis configuration. The following graphic shows the different areas of the "Vibration Characteristic Values" window:

① Save, cancel or delete changes

② Packages name

③ Input fields for name and description of the analysis

④ Input fields for the settings of the analysis

⑤ Available calculations

⑥ Assignments of this Analysis Package is within the Project

Parameter of "Vibration Characteristic Values"¶

The following table shows the parameters of the "Vibration Characteristic Values" window:

| Area | Parameter | Description |

|---|---|---|

| General | Analysis Package Name | Add an individual name for your analysis package. |

| Description | Add an individual description (optional). | |

| Settings | Calculation Interval [s] | Add the time interval for the calculation of new values. |

| Upload Interval [min] | Add the time interval for the upload of the calculated values to Insights Hub | |

| . | ||

| Calculations | Data Storage Asset | - Select the asset your configuration is related to. - Change to Insights Hub Monitor to see the respective data. |

| RMS Velocity | The RMS (Root Means Square) of a velocity signal provides information about the energy content of a vibration. The RMS is calculated from the dominant frequency component. Due to this fact, this quantity provides only information about the general condition of a machine or component. Therefore, it is impossible to detect changing vibration frequencies or new developing frequency components caused by a beginning damage. The velocity RMS value is a crucial quantity in order to detect inappropriate behavior of stationary machine components. In order to receive the velocity signal, the input acceleration signal is converted into a velocity signal automatically. It has to be considered that the amplitudes above 1500 Hz are attenuated because of the integration. | |

| Peak-Peak Velocity | The peak-peak value of a velocity signal can be calculated as auxiliary quantity to the velocity RMS in order to detect inappropriate behavior of stationary machine components. In order to receive the velocity signal, the input acceleration signal is converted automatically into a velocity signal. It has to be considered that the amplitudes above 1500 Hz are attenuated because of the integration. | |

| Zero-Peak Velocity | The zero-peak value of a velocity signal can be calculated as auxiliary quantity to the velocity RMS in order to detect inappropriate behavior of stationary machine components. In order to receive the velocity signal, the input acceleration signal is converted automatically into a velocity signal. It has to be considered that the amplitudes above 1500 Hz are attenuated because of the integration. | |

| RMS Acceleration | The RMS (Root Means Square) of an acceleration signal provides information about the energy content of a vibration. The RMS is calculated from the dominant frequency component. Due to this fact this quantity provides only information about the general condition of a machine or component. Therefore, it is impossible to detect changing vibration frequencies or new developing frequency components caused by beginning damage. The acceleration RMS value is a crucial quantity in order to detect inappropriate behavior of stationary machine components. | |

| Peak-Peak Acceleration | The peak-peak value of an acceleration signal can be calculated as auxiliary quantity to the acceleration RMS in order to detect inappropriate behavior of stationary machine components. | |

| Zero-Peak Acceleration | The zero-peak value of an acceleration signal can be calculated as auxiliary quantity to the acceleration RMS in order to detect inappropriate behavior of stationary machine components. | |

| Crest Factor | The crest factor of a signal is the ratio of the zero-peak value to the RMS. A typical acceleration signal from a machine with a large imbalance possesses a crest factor similar to √2. But as the bearings begin to wear and impact begins to occur, the crest factor has a higher value than this. Therefore, this quantity is very important for evaluating rolling bearing. |

Last update: January 22, 2024